Key Takeaways

Navigating the environmental impact of compostable plates versus plastic requires a thorough, data-driven understanding of their material composition, lifecycle emissions, and real-world disposal outcomes. The following key takeaways synthesize current research and standards to equip you with the clarity and precision needed for informed decision-making.

- Recognize material nuances to understand true impact: Compostable plates frequently use materials like PLA (polylactic acid), bagasse, or molded fiber, whereas plastic plates typically consist of PET, PP, or PS—each differing in production emissions, biodegradability, and environmental persistence.

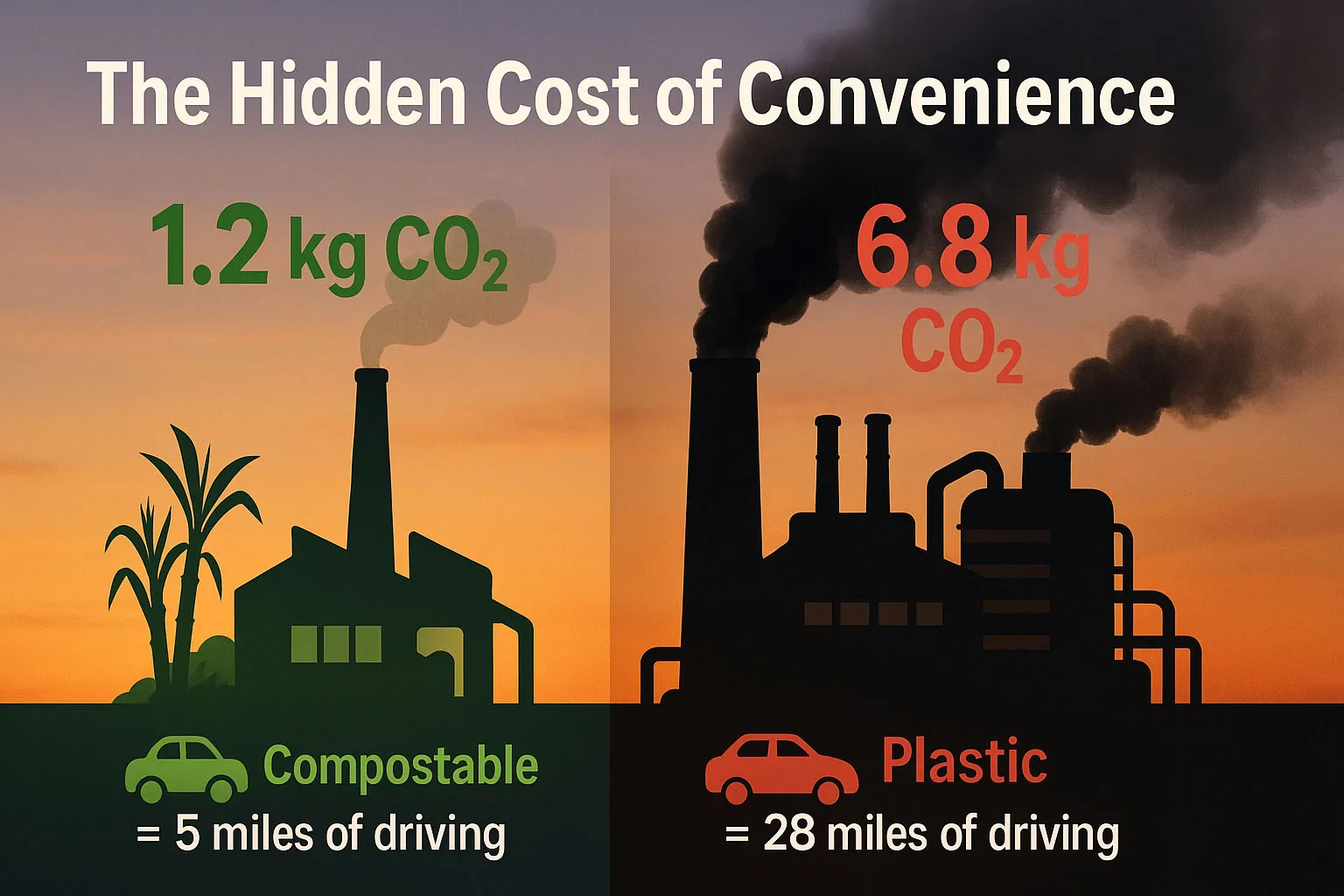

- Leverage lifecycle assessments to evaluate carbon trade-offs: While some compostable materials exhibit higher initial greenhouse gas emissions due to agricultural inputs and processing, these can be offset through industrial composting, contrasting with the long-term pollution risks of petroleum-based plastics.

- Match disposal methods with material requirements: Certified compostable plates (meeting ASTM D6400 or EN 13432) biodegrade effectively only in industrial composting facilities; home composting and landfills usually fail to deliver complete degradation, sometimes exacerbating greenhouse gas emissions.

- Prevent recycling contamination through consumer education: Introducing compostable plates into plastic recycling systems can cause significant contamination and operational challenges, emphasizing the need for clear labeling and public awareness campaigns.

- Scrutinize certifications to cut through labeling confusion: Familiarity with ASTM D6400 and EN 13432 standards helps verify which products are genuinely compostable—and under what conditions—safeguarding against misleading “biodegradable” claims.

- Balance performance and cost considerations alongside environmental goals: Compostable plates may exhibit limitations such as lower heat tolerance and higher costs when compared to plastic, affecting their fit for different use cases and consumer preferences.

- Prioritize reusable or optimized waste management practices: Where feasible, reusable plates or optimized waste streams combining compostable options with rigorous audits maximize environmental benefits and minimize contamination risks.

- Customize choices by local waste infrastructure realities: The net environmental advantage hinges on regional access to industrial composting and efficient waste management systems, underscoring the importance of localized disposal strategies.

Understanding these complexities lays the foundation for responsible, context-aware choices. The sections that follow explore deeper insights into material properties, lifecycle data, disposal pathways, and actionable recommendations across diverse real-world contexts.

Understanding the Material Nuances: Types of Compostable Plates vs Plastic Plates

A precise environmental comparison of compostable plates versus plastic begins with a close examination of the distinct materials in each category, as these define production footprints, biodegradability, and end-of-life behavior. Compostable plates commonly utilize:

- PLA (polylactic acid): A bioplastic derived from renewable resources such as corn starch or sugar beets. PLA plates mimic the look and feel of conventional plastics but require industrial composting conditions—with controlled heat and moisture—for effective biodegradation.

- Bagasse: Made from sugarcane fiber waste, bagasse plates are sturdy, microwavable, and naturally biodegradable in composting environments, frequently used in food service for their renewable origins and functional benefits.

- Molded fiber: Created from recycled paper or wood pulp, these plates offer a fiber-based, biodegradable option prized for its low environmental impact and biodegradability in suitable composting settings.

In contrast, plastic plates primarily consist of:

- PET (polyethylene terephthalate): Valued for its lightweight, transparency, and widespread recyclability where facilities exist, PET is a common plastic used for disposable plates.

- PP (polypropylene): Known for its heat resistance and durability, PP is used in both disposable and reusable plates but depends fully on fossil fuel supply chains.

- PS (polystyrene): Characterized by rigidity and low cost, PS is the least environmentally friendly option due to poor recyclability and toxic emissions when incinerated, contributing to pollution concerns.

From a production perspective, compostable materials generally incur higher upfront greenhouse gas emissions owing to agricultural cultivation, land use, and processing energy demands. Meanwhile, plastic plates typically have lower immediate carbon footprints, leveraging fossil fuel-based feedstocks. However, this initial advantage is often offset by plastics’ persistence in the environment, where they contribute extensively to pollution and resource depletion.

This intricate material profile underscores the necessity of aligning product choice with compatible waste management infrastructure and disposal realities to achieve meaningful environmental outcomes.

Lifecycle Emissions & Carbon Footprint: Compostable Plates vs Plastic

A comprehensive environmental assessment must incorporate the full lifecycle emissions of compostable versus plastic plates, spanning production, usage, and disposal stages. Lifecycle assessments (LCAs) reveal that producing compostable plates—especially those made from PLA and bagasse—often consumes 10–30% more energy and generates higher greenhouse gas emissions upfront compared to conventional plastic options like PET and PP. This disparity largely stems from agricultural practices, fertilizer application, and processing energy, whereas plastic manufacturing, though reliant on fossil fuels, tends to be more energy-efficient per unit produced.

Functionally, plastic plates outperform most compostables in heat resistance, mechanical strength, and durability. These traits enable plastic plates to withstand microwaving without deformation and reduce breakage-related waste. Recent innovations have improved bagasse plates’ thermal and structural capabilities, permitting safe use with hot foods and microwave heating, whereas PLA plates remain more sensitive to heat, limiting certain applications.

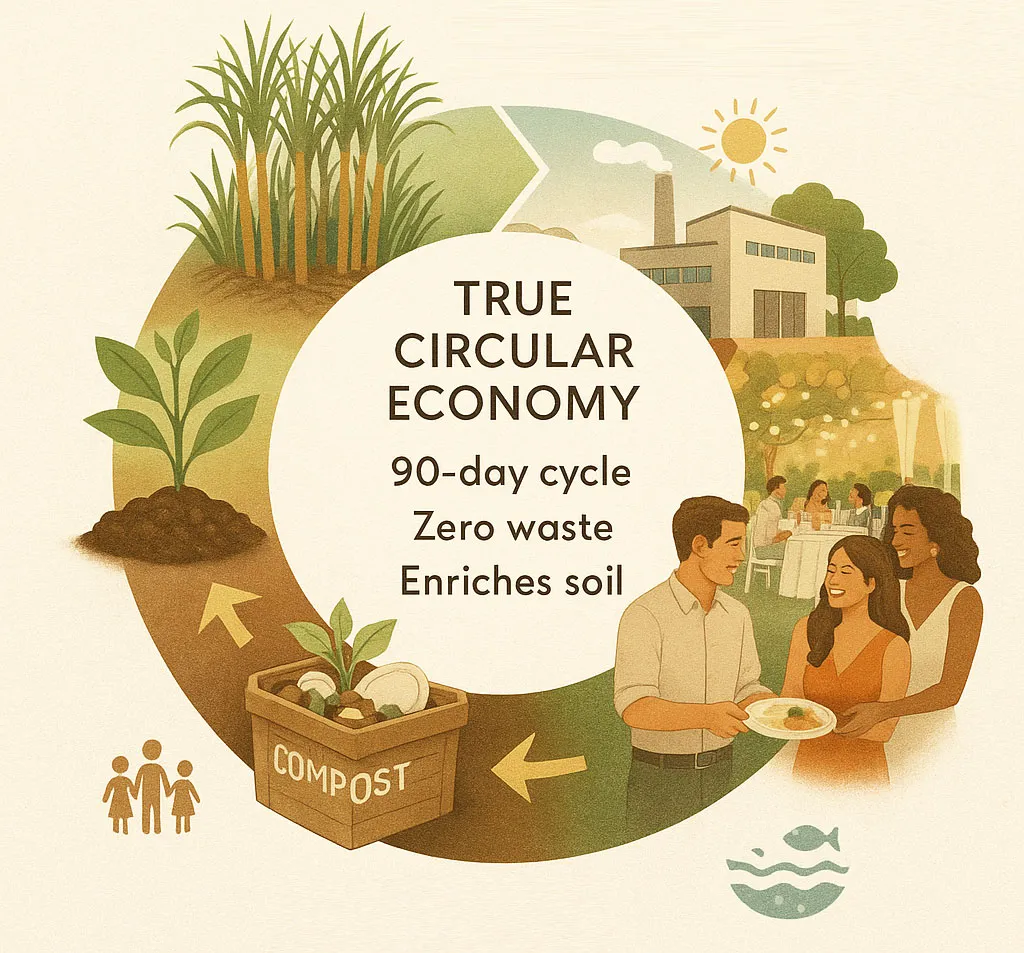

The environmental benefits of compostable plates become evident primarily during the disposal phase. When processed through certified industrial composting, these plates biodegrade into carbon dioxide, water, and organic biomass within 90–180 days, effectively offsetting some upstream emissions and preventing persistent environmental contamination. Plastic plates, by contrast, degrade extremely slowly, fragmenting into microplastics that accumulate in soil, waterways, and oceans, with deleterious impacts on ecosystems and human health.

For example, a university event replacing polystyrene plates with bagasse alternatives coupled with strong industrial composting protocols yielded a 25% reduction in the event’s overall carbon footprint and significantly reduced waste sent to landfill. Similar benefits have been noted in corporate cafeterias and hospitality sectors adopting compostable options aligned with robust disposal systems.

End-of-Life Realities: Disposal Outcomes of Compostable Plates vs Plastic

The ultimate environmental performance of compostable plates vs plastic hinges critically on disposal methods. Certified compostable plates engineered to meet ASTM D6400 (US) or EN 13432 (EU) require industrial composting facilities, where controlled elevated temperatures (above 55°C), moisture, and microbial activity enable complete biodegradation within 90 days. Without such conditions:

- Home composting typically lacks sufficient heat intensity and consistency, leading to slow or incomplete breakdown of compostable plates.

- Landfills cause anaerobic decomposition, producing methane—a greenhouse gas approximately 28 times more potent than carbon dioxide over a 100-year timeframe—thereby negating climate benefits. Compostable plates in landfill may persist for years with limited degradation.

Plastic plates remain largely inert in landfills, persisting for centuries and slowly breaking down into microplastics that contaminate terrestrial and aquatic ecosystems. Their resistance to biodegradation highlights significant environmental concerns tied to plastic waste accumulation.

Additionally, compostable plates are incompatible with conventional plastic recycling streams. Their inadvertent inclusion causes contamination in recycling batches, triggering costly sorting challenges and reducing overall recycling efficiency. This reality underscores the crucial role of:

- Clear, standardized labeling to guide consumers and waste managers.

- Public education campaigns to ensure correct sorting and disposal.

Ultimately, the environmental advantage of compostable plates is conditional—dependent more on regional composting access and consumer behavior than on the inherent properties of the materials alone. Organizations and individuals must therefore evaluate local infrastructure and prioritize waste education to harness the full potential of compostable alternatives.

Certifications and Labeling: Navigating ASTM D6400, EN 13432, and Consumer Confusion

In a marketplace crowded with “biodegradable,” “eco-friendly,” and “compostable” claims, distinguishing genuinely compostable products demands familiarity with key certifications:

- ASTM D6400 (U.S.): Verifies that products biodegrade under industrial composting conditions within 180 days without releasing harmful residues.

- EN 13432 (EU): Similar standard confirming industrial compostability in European facilities, including biodegradation, disintegration, and ecotoxicity criteria.

Products bearing these certifications guarantee breakdown behavior only in specific industrial composting settings and are not suited for home composting or recycling.

Many “biodegradable” products lacking such certification may degrade very slowly or unpredictably, undermining waste diversion efforts. This discrepancy breeds considerable consumer confusion and improper disposal, weakening environmental outcomes.

Procurement professionals, event planners, retailers, and consumers are advised to:

- Prioritize certified products aligned with local composting infrastructure.

- Engage with waste management providers to confirm facility capabilities.

- Verify certification marks before purchase to avoid misleading green claims.

Enhancing certification transparency and harmonizing labeling standards globally remain ongoing challenges, requiring collaboration between manufacturers, regulators, and waste management stakeholders.

Practical Considerations: Cost, Performance, and Consumer Disposal Behavior

Beyond environmental attributes, practical factors deeply influence the choice between compostable plates and plastic:

- Cost: Compostable plates often come with a 15–50% price premium over plastic alternatives due to higher raw material expenses, certification costs, and lower production volumes. Bulk purchasing and regional sourcing strategies can alleviate some cost pressures but may not fully close the gap.

- Performance: Bagasse plates exhibit good microwave compatibility and heat resistance, making them suitable for many foodservice applications. PLA plates’ lower heat tolerance constrains their use with hot foods or microwaving. Plastic plates, particularly those of PP and PET, excel in durability, stacking strength, and breakage resistance, reducing incidental waste but at environmental expense.

- Disposal behavior: Consumer actions often undermine compostable plates’ advantages; studies show many users default to landfill disposal where industrial composting is unavailable. Event organizers and vendors can improve composting rates significantly through targeted staff training and clear, visible signage. A catering company implementing comprehensive education programs documented a 75% increase in compost diversion within six months.

- Regulatory and supply chain context: Some jurisdictions incentivize compostable product use or impose restrictions on single-use plastics, influencing procurement strategy and waste management planning.

Balancing these considerations is key to tailoring sustainable choices suited to operational realities and environmental goals.

Alternatives and Recommendations: Reusable Plates, Recycling, and Waste Audits

The compostable vs plastic debate expands naturally to encompass more holistic and sustainable waste practices:

- Reusable plates: Durable options—ceramic, glass, metal, or heavy-duty plastic—dramatically reduce lifecycle environmental impacts when washed and reused multiple times. Initial capital and infrastructure investments can be offset by lifecycle savings in waste and materials.

- Recycling optimization: For plastic plates still in use, ensuring sorting aligns with local recycling streams—favoring PET and PP—and minimizing non-recyclable plastics or contamination improves circularity and resource recovery.

- Localized waste audits: Conducting comprehensive audits helps venues identify actual waste generation and management capacities. This data-driven approach enables selecting plate materials compatible with existing composting or recycling facilities and informs effective staff training and guest communication.

- Integrated waste management plans: Combining reuse, compostable materials, and recycling within a coherent framework maximizes diversion rates and environmental performance. For example, some institutions employ hybrid strategies—using reusable plates onsite for seated dining and compostables for takeaway packaging complemented by targeted composting programs.

Implementing these approaches requires strategic engagement with suppliers, waste haulers, and facility managers alongside continuous monitoring and iterative improvement to ensure sustained benefits.

Latest Insights: Leveraging AI to Optimize Waste Management and Material Selection

Cutting-edge artificial intelligence (AI) technologies are transforming how organizations navigate the compostable plates vs plastic landscape. AI-powered platforms facilitate data-driven procurement and waste logistics optimized to local infrastructure realities:

- Tools like AI Field Agents integrated with data repositories (e.g., Airtable) can monitor recycling contamination rates, composting facility acceptance, and material-specific disposal success in real time.

- AI assistants can provide instant recommendations on the ideal plate types for particular venues based on local service availability, weather conditions, and event parameters.

- Automation scripts track inventory, plate usage patterns, and waste diversion efficiency, offering actionable insights for continual procurement adjustment.

- Predictive analytics can foresee contamination risks or disposal mismatches, enabling preemptive education campaigns or alternative material sourcing to mitigate environmental impacts.

For example, a large conference center implementing AI-driven waste management witnessed a 30% increase in composting efficiency and a substantial reduction in recycling contamination within a year, showcasing AI’s potential in promoting sustainable event operations and material lifecycle optimization.

Conclusion

Effectively navigating the complex terrain of compostable plates versus plastic demands not only an understanding of material science and lifecycle impacts but also a nuanced appreciation of disposal infrastructure and consumer behavior. Aligning purchasing choices with validated certifications, local waste processing capabilities, and comprehensive education strategies ensures that decisions deliver genuine environmental benefits rather than unintended consequences. Looking forward, sustainable success will favor entities that adopt adaptable, data-informed strategies—leveraging innovations like AI-driven waste management—while cultivating collaboration across supply chains, waste handlers, and end-users. The real challenge and opportunity lie not in choosing the latest “green” product but in orchestrating a circular, transparent, and effective waste ecosystem that anticipates change and drives measurable impact.

![[100 COUNT]Harvest Pack PFAS FREE 9-inch Round Disposable Compostable Paper Plates, Heavy-Duty Natural Bagasse Biodegradable Dinner Plate, Large plate, From Eco-Friendly Sugarcane Plant Fibers](/_next/image?url=https%3A%2F%2Fm.media-amazon.com%2Fimages%2FI%2F31Yb8TZ3SEL._SL500_.jpg&w=3840&q=75)

![Stack Man 100% Compostable Paper Plates 9 Inch Heavy-Duty [125-Pack] Eco-Friendly White Bagasse Disposable Plates Made of Natural Sugarcane Fibers - 9" Biodegradable Plate (BPI-Certified) (PFAS-Free)](/_next/image?url=https%3A%2F%2Fm.media-amazon.com%2Fimages%2FI%2F41B1Kr8RLiL._SL500_.jpg&w=3840&q=75)

![Stack Man 100% Compostable Paper Plates 10 Inch Heavy-Duty [125-Pack] Eco-Friendly White Bagasse Disposable Dinner Plates From Natural Sugarcane - 10" Biodegradable Plate (BPI-Certified) (PFAS-Free)](/_next/image?url=https%3A%2F%2Fm.media-amazon.com%2Fimages%2FI%2F412vOQo2O2L._SL500_.jpg&w=3840&q=75)